Plant-based recombinant expression systems offer a highly reproducible platform for synthesizing recombinant human collagen, effectively overcoming the limitations associated with animal-derived and cadaver-sourced collagens. This makes them an ideal collagen source for tissue engineering and regenerative medicine applications. Furthermore, utilizing plant cells or whole plants as expression systems for synthesizing recombinant human collagen holds promising prospects, featuring lower costs, enhanced scalability, absence of animal-related risks, and high design flexibility.

Lifeasible provides advanced technical support and comprehensive solutions for plant-based production of recombinant human collagen. By utilizing plants as bioreactors to produce target proteins, we offer a cost-effective, highly scalable collagen source that matches the mechanical properties and functionality of natural human collagen while eliminating concerns about immunogenicity and disease transmission associated with animal-derived collagens.

Our plant-expressed full-length human collagen overcomes the limitations of traditional animal-derived and microbial fermentation collagens by utilizing plant bioreactor technology to produce collagen that aligns with human physiological characteristics.

Our plant expression platform employs transgenic technology to integrate human collagen genes and their key modifying enzymes, enabling proper collagen folding and post-translational modifications. We have established an advanced plant-based collagen production platform utilizing Nicotiana benthamiana plants for collagen synthesis. Our sophisticated plant-based collagen production system yields collagen with optimal hydroxylation levels, enabling rapid protein cultivation, extraction, and processing within condensed timelines.

We design and optimize genes encoding human collagen sequences according to client requirements (e.g., specific collagen types I, II, III) and construct efficient, stable plant expression vectors to ensure high-yield expression and accurate post-translational modification of the target proteins.

We offer multiple plant expression system options, including transient expression and stable transgenic lines. Utilizing advanced Agrobacterium-mediated transformation technology, we efficiently introduce target genes into plant hosts such as Nicotiana benthamiana. As plants continue to grow, the target protein is expressed in their leaves. Plants are harvested after one to two weeks, and leaves undergo simple purification to recover high-purity proteins. During this process, we can design Agrobacterium to direct the expressed proteins into specific plant cellular compartments based on required post-translational modifications (PTMs), thereby protecting them from the extracellular environment.

Our state-of-the-art controlled-environment growth facilities and bioreactor technologies support scalable plant cultivation and biomass expansion. Production capacity can be rapidly scaled from gram-level to tens of kilograms of plant material, laying a solid foundation for industrial production.

We have established robust and scalable downstream purification workflows encompassing extraction, filtration, and chromatography steps. This ensures the final collagen product exhibits exceptional purity, intact biological activity, and complete removal of plant-specific impurities.

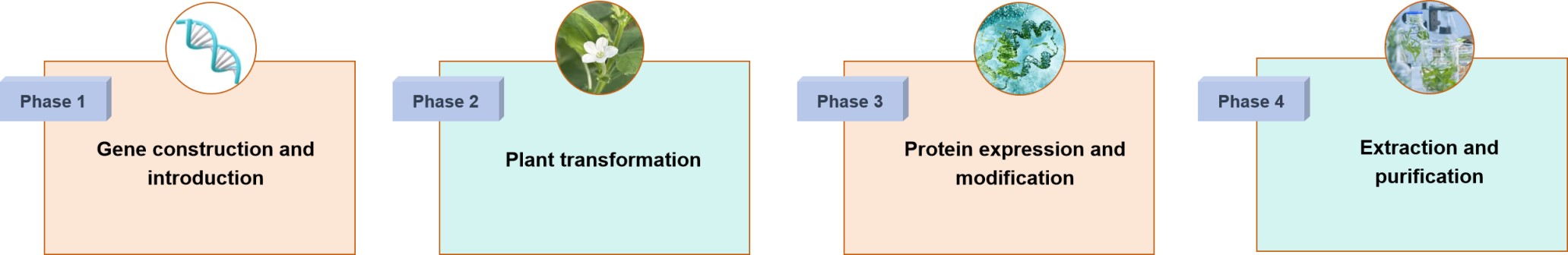

Fig.2 Our service process. (Lifeasible)

Fig.2 Our service process. (Lifeasible)

Advancements in synthetic biology and plant molecular agriculture will further optimize hydroxylation efficiency, increase yields, and enable the development of novel collagen variants. Lifeasible remains committed to advancing this technology's industrialization, providing customers with safe, high-performance recombinant collagen solutions. If you are interested, please feel free to contact us.