Obtaining tissue structures from muscle cells is an efficient way to produce cultured meat. However, it is difficult to culture cells in a culture medium and obtain similarly structured tissues without the proper provision of scaffolds. Therefore, scaffolds are needed to provide better cell proliferation, differentiation, and tissue development. Scaffolds often play a crucial role in ensuring the movement of oxygen, nutrients, and waste products in and out of cells, controlling the geometry and cell type distribution of the growing tissue and providing structure to the final product. In addition, innovation in scaffold technology is needed to make cultured meat exactly mimic the sensory and nutritional properties of traditional meat2. Many scaffold technologies have been developed for biomedical tissue engineering. However, cultured meat production has a unique set of limitations in terms of production scale and cost, as well as the necessary properties of the final product.

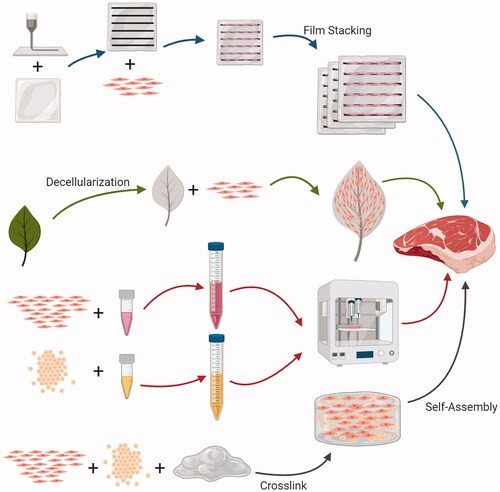

Fig.1. Scaffolds for the manufacture of cultured meat. (Seah J S H et al., 2022)

Fig.1. Scaffolds for the manufacture of cultured meat. (Seah J S H et al., 2022)

To produce structured and thick meat products, cells must be transferred to the scaffold. Working closely with experts in tissue engineering, regenerative medicine, and biomaterials science, Lifeasible is committed to developing sustainable and edible scaffolds to reconstruct the complex multicellular structure of the meat. The biomaterials that make up the scaffold determine many of its downstream properties. We will consider a variety of different material properties in selecting the right scaffold for cultured meat based on our customers' requirements. We develop the following polymers as scaffold materials, including but not limited to:

Our goal is to provide edible, cost-effective, and sustainable materials and methods to support the culture, expansion, and differentiation of cells used in cultured meat. The customized scaffolds we have developed have been widely welcomed by our customers worldwide.

We offer textured plant proteins as scaffolds for culturing meat. We also develop customized textured plant protein compositions to improve parameters such as pore size, nutritional value, texture, and elasticity of scaffolds.

In addition, we use commonly used scaffold manufacturing techniques such as particle leaching, melt forming, freeze drying, and gas foaming to make edible synthetic polymers into scaffolds for cultured meat.

Hydrogels mimic the structure of the naturally occurring extracellular matrix. We develop hydrogels as 3D matrix fillers inside porous scaffolds, as components of bioinks, or as source materials for developing porous scaffolds.

We have advanced spinning technologies (electrostatic spinning and rotary jet spinning) for the production of nanofibers with a variety of properties useful for cultured meat. This technology can be applied to various materials, including PLA, PLGA, fibronectin, albumin, gelatin, etc.

While scaffolds offer many advantages for tissue engineering, including the ability to facilitate oxygen and nutrient transport and precise control of the 3D geometry of the final construct, here, Lifeasible also offers scaffold-free approaches based on cell sheets or organoids to create larger structures of cultured meat.

The role of each specific material in the scaffolding requires us to be very innovative in the development phase to achieve each customer's individual goals. Our labs are rigorously testing various materials and components to obtain more scalable and cosmetically pleasing cultured meat. Scaffolding will continue to be modified to support the diversity of cell types and meat products to be manufactured in the future. We guarantee you obtain edible scaffolding at competitive prices, with short turnaround times and reliable results. Feel free to contact us for more information.

Reference