Bacterial cellulose (BC) is a natural cellulose material synthesized by bacteria, also known as microbial cellulose. The main strains of bacteria capable of synthesizing BC are Acetobacter, Agrobacterium, Pseudomonas, Rhizobium, and Sarcina. Bacterial cellulose has high purity, high polymerization, high crystallinity, high biocompatibility, biodegradability, bioadaptability, and no allergic reactions, as well as high water-holding and crystallinity, good nanofiber network, high tension and strength, and good mechanical toughness. With its excellent properties and wide range of applications, bacterial cellulose has high commercial value, and the product can be modified and modified in various ways to broaden its applications.

There are two main methods for the chemical modification of BC: small molecule chemical modification, including adsorption of surfactants or polyelectrolytes, esterification, etherification, silylation, etc.; the second is graft copolymerization. Chemical modification can be used to improve the dispersion of nanocellulose in solvents by introducing stable positive or negative charges on the surface, effectively preventing particle agglomeration, and increasing its stability and dispersion to meet the needs of various practical applications, or combining non-polar or hydrophobic substances on the surface to reduce its surface free energy and improve its interfacial compatibility in composites.

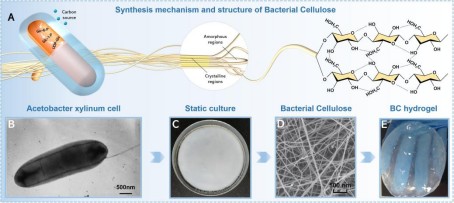

Fig.1 Synthesis approach and hierarchical structures of BC at multiple length scales. (Pan, X., et al., 2023)

Fig.1 Synthesis approach and hierarchical structures of BC at multiple length scales. (Pan, X., et al., 2023)

Lifeasible has advanced technology for bacterial cellulose modification to assist customers in the development of modified products. Currently, the modification services we can provide include the following.

Cationization of cellulose can change the nature and distribution of charge on the fiber surface to achieve improved performance in dispersibility and adsorption. Amination modification is generally achieved by etherification reactions with cationization reagents, bonding cationic groups such as quaternary ammonium salts to the hydroxyl sites, etc.

Due to the presence of many polar hydroxyl groups, cellulose can undergo esterification reactions with various inorganic or organic acids to introduce functional aliphatic groups of different chain lengths on the molecular chain to achieve functional modifications. Esterification of cellulose by nucleophilic substitution reactions has resulted in cellulose ester materials with superior properties. Depending on the structural properties of the esterified precursor materials and the type of esterification, several types of esterified products have been formed.

Silylation of cellulose using a silane coupling agent to replace the hydroxyl group on cellulose can achieve modification of cellulose hydrophobicity and improve the chemical activity of in situ composite polymers on the cellulose surface.

Suitable physical and chemical means are selected to excite free radical activity on the cellulose surface, which attracts monomers to graft at hydroxyl sites through covalent or non-covalent bonding and subsequently triggers the polymerization process of monomers on the cellulose surface. The grafting modification of the polymers improves the dispersion of cellulose in the solvent on the one hand and imparts functional modifications to its composite system on the other hand.

2,2,6,6-Tetramethylpiperidine-1-oxyl radical (TEMPO) is a piperidine-like nitroxide radical that, when coexisting with other oxidizing agents, achieves highly selective oxidation of the primary hydroxyl group at the C6 position on the cellulose molecule and has no modifying effect on the secondary hydroxyl group.

In addition to the above-mentioned modification solutions, we also offer other technical support for bacterial cellulose. If you are interested in our solutions and technologies, please feel free to contact us.

Reference