Thaumatin is considered a safe and natural zero-calorie sweetener that has been approved for use in many countries. Used as a flavor modifier in food applications such as ice cream, chewing gum, dairy products, pet food, and soft drinks, and to mask undesirable flavors in food and pharmaceuticals. However, natural sources of thaumatin are limited and insufficient to meet the growing demand. Therefore, producing recombinant thaumatin using microbial systems is an attractive option to overcome the limitations of natural extraction and chemical synthesis.

For many years, Lifeasible has been deeply involved in the sweet protein field. We have built an advanced plant gene editing platform, and our scientists have extensive experience in developing microbial strains. Providing you with thaumatin production strains development service is one of our specialties, and we will help you to explore thaumatin in-depth, especially its potential as a natural sweetener and flavoring agent.

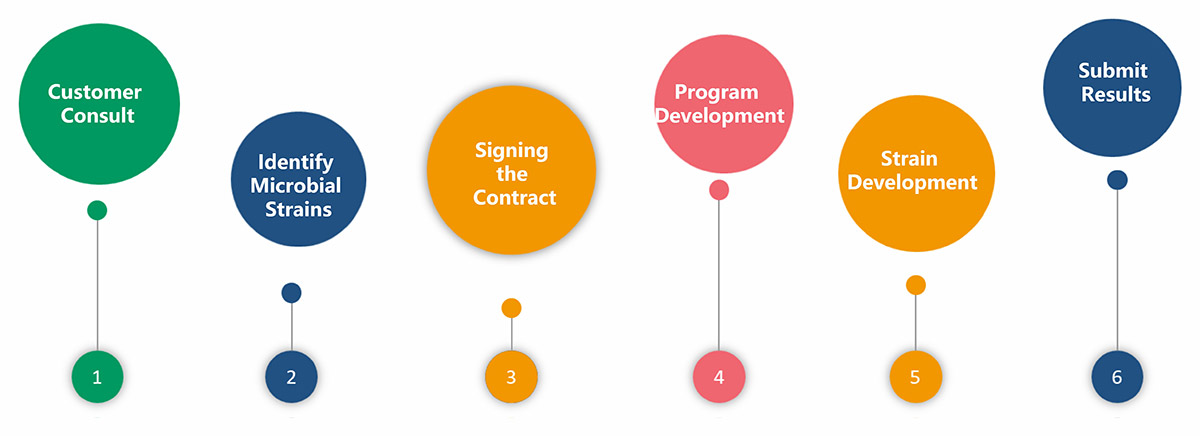

Microbial systems are undoubtedly one of the best means to achieve large-scale expression of recombinant proteins. The development plan Lifeasible provides to customers covers every step, from assay design to successful strain development. We pay attention to all the details and strive to meet all the requirements of our customers. To improve the stability and expression of thaumatin I and II, we will select suitable strains, vectors, and restriction sites.

| Service Step | Service Content |

| Microbial strains and media | The first step is to determine the host strain and select the appropriate medium according to different host strains. |

| Construction of vectors for over-expression of thaumatin gene | The second step involves selecting restriction sites and resistance screening tags, cloning the thaumatin gene, and coupling it with multiple expression cassettes. E. coli DH5α is then used to amplify the vector carrying the thaumatin gene. |

| Transformation of host strains | Plasmid transformation is used to transform the vector carrying the thaumatin gene into the host strain, and DNA sequencing will be used to verify the transformants in the screening medium. It will be saved for the next experiment, the transformants that successfully transferred into the thaumatin gene. |

| Purification of recombinant thaumatin | The culture fluid of the host strain is collected, and the recombinant thaumatin is purified with a Sephadex G-25 column or the like. |

| Analysis of recombinant thaumatin (optional) | N-terminal amino acid sequence, sensory analysis, etc., can be used for subsequent analysis of recombinant thaumatin. |

Technical means: plasmid transformation

Microbial strains that can be developed: Saccharomyces cerevisiae, Pichia pastoris, Streptomyces lividans, Aspergillus niger var, Aspergillus awamori, E. coli DH5α, etc.

Vectors: double transformant TB2b1-44-GD5, pAN7-1, pPICZB, pBluescript KS+, etc.

Delivery results: microbial strains capable of expressing thaumatin, experimental data, pictures, and standard experimental reports.

"Science, authenticity, efficiency and professionalism" is the philosophy that Lifeasible always upholds. We serve our clients as a professional CRO that can provide one-stop solutions for developing microbial systems that express thaumatin. If you would like to work with us, please contact us directly.

References