Spider silk has excellent mechanical properties, such as high resistance and elasticity, and most importantly, its versatility, which makes it more promising than other natural and man-made fibers. Lifeasible offers services for the expression and purification of recombinant spider silk proteins, the production of spider silk proteins into spider silk fibers and the testing of spider silk fibers.

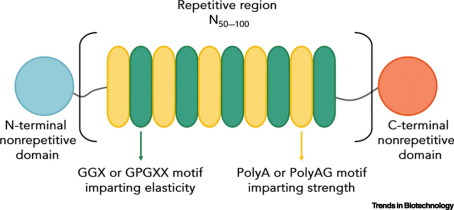

The mechanical properties of spider silk fibers superior to those of most synthetic or natural, high-performance fibers are closely related to the tandem arrangement of amino acid repeats in spider silk proteins. A single multiple repeat module of a certain type of spider silk protein is performed. The repeat module's ends contain either the N-terminal and C-terminal non-repetitive regions or a single C-terminal non-repetitive region. The repetitive modules were repeated as a combination, plasmids were constructed, expression was purified in E. coli, silk fibers were obtained by hand-drawing, and the secondary structure of spider silk protein was tested to investigate the secondary structure changes of the protein before and after silk formation. The mechanical properties of the silk fibers were tested and analyzed.

Fig.1 Modular Structure of a Spidroin Protein. (Whittall et al., 2021)

Fig.1 Modular Structure of a Spidroin Protein. (Whittall et al., 2021)

Firstly, the vector was constructed, and the plasmid was double digested for 2 h. The plasmid was subjected to two-step PCR using primers to obtain the target fragment. The target fragment and the vector were subjected to agarose gel electrophoresis, followed by gel recovery. The small fragment obtained by gel recovery was double digested and then recovered by PCR.

A single plasmid clone was picked, inoculated into a medium containing ampicillin, shaken, and incubated overnight. The culture broth is expanded, and expression is induced by adding reagents. The cultured broth can be used directly for the next purification step or centrifuged and lyophilized. To maximize the expression of spider proteins, the protein expression and purification conditions need to be mapped in advance to determine the optimal expression temperature and purification method for the target protein.

Purification by affinity chromatography.

The target protein obtained from the purification is concentrated by concentration tube, and repeatedly centrifuged, and the concentrated target protein is transferred to a clean slide with a pipette, and the droplets are gathered as much as possible without dispersion, left to stand, and spider silk fibers are slowly pulled out from the droplets with forceps.

A scanning electron microscope was used to observe the morphology of the silk fibers, and the pictures were taken at different magnifications.

The mechanical properties of the spider fibers were tested using a nano-tensiometer. The spider fibers were stretched at a certain speed until they broke. The force profile of the spider fibers was obtained by software, and the related mechanical properties were calculated.

The secondary structure of the spider fibers is tested on the carrier table of the Fourier infrared spectrometer, and the software is used to process the data and estimate the secondary structure content from the peak area.

If you are interested in our services, please feel free to contact us, and we will provide you with a customized solution.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

Why Do Plants Blush When They Are Hungry?

April 26, 2024

STU-CRISPR System Improves Plant Genome Editing Efficiency

April 19, 2024