Most of the bioactive compounds of microalgae are stored intracellularly and require cell wall rupture for recovery. The wide application of microalgal biomass as feedstock also encounters the challenge of efficient recovery of intracellular active compounds from biomass, where the elastic cell wall structure of some microalgal species becomes an obstacle to the industrial development of microalgae. In most cases, solvents are used to extract intracellular compounds from untreated, chemically treated, or mechanically treated biomass. However, due to the insect resistance, complexity, and diversity of microalgal cell walls, extraction of compounds from intracellular cells require high energy input or large amounts of chemicals. Therefore, there is a need to develop effective and low-cost cell fragmentation techniques to pretreat algal biomass to release bioactive compounds stored in the cells.

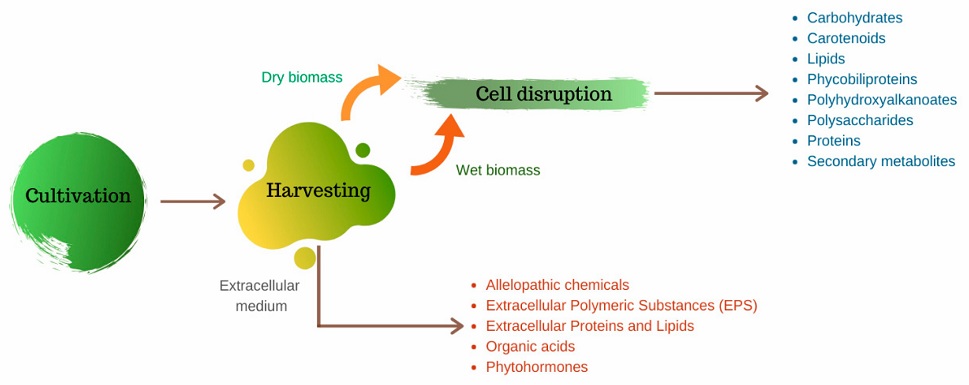

Fig 1. First steps in microalgae production, from cultivation to harvesting and cell disruption, for extraction or recovery of intracellular and extracellular components. (Corrêa P S, et al., 2020)

Fig 1. First steps in microalgae production, from cultivation to harvesting and cell disruption, for extraction or recovery of intracellular and extracellular components. (Corrêa P S, et al., 2020)

The first step in isolating and identifying microalgal bioactive compounds is microalgal cell fragmentation. Our skilled scientists have been working on the biochemical components of microalgal cell walls for many years. They are very familiar with the structure, composition, and biosynthesis of microalgal cell walls. Here at Lifeasible, we provide expert microalgal cell wall rupture service by employing various energy-efficient cell fragmentation techniques to maximize the extraction of desired active compounds from microalgal biomass.

Based on your desired end bioactive product, we will develop the best microalgae cell wall pretreatment solution.

Depending on the microalgae species and the nature of the target product, we will select the appropriate microalgal cell rupture method for you to improve the extraction efficiency and quality of the bioactive compound and lay the foundation for the subsequent purification steps. If you are interested in our solutions for cell wall rupture of microalgae, please contact us directly.

Reference

Lifeasible has established a one-stop service platform for plants. In addition to obtaining customized solutions for plant genetic engineering, customers can also conduct follow-up analysis and research on plants through our analysis platform. The analytical services we provide include but are not limited to the following:

STU-CRISPR System Improves Plant Genome Editing Efficiency

April 19, 2024

Application of Exosomes in Facial Beauty

April 12, 2024